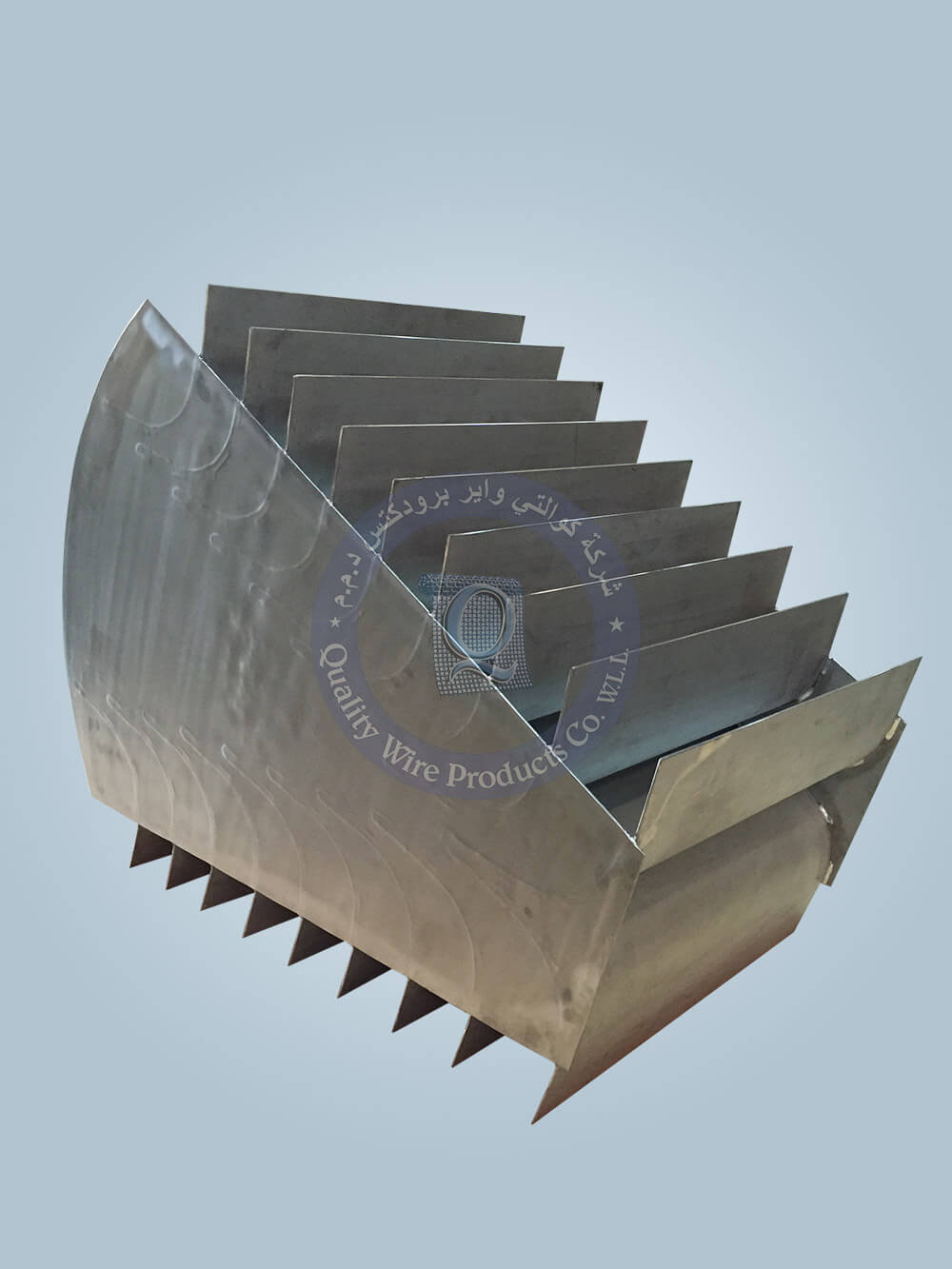

VANE PACKS

Vane packs separators, are most widely used to separate liquid droplets carried by gaseous streams

Working principle

Vane packs are composed by sets of vane profiles where the gas passes through, the water content condenses and slides down along the vanes and are drained down into the liquid section of the vessel.

- Vane packs separators are used for separating relatively big droplets because of the big diameter.

Typical Applications

- Low Pressure Evaporators.

- Refinery Vacuum towers.

- Scrubbers in flue gas desulfurization (FGD) systems.

- Pulp and Paper mills.

- Sugar refinery.

Benefits

- Suitable for eliminating solids or sticky and viscous liquids.

- Suitable for both vertical and horizontal gas flow.

- High collection efficiency.

- Can handle high liquid and gas loads.

For high performance vane packs it is attached with

- Wire mesh: when the diameter of the vessel is too small to install a properly sized wire mesh demister so the diameter will increase and the efficiency will be higher.

- Perforated sheet: to a sure good disruption of a gas flow inside the vessel.