We were asked to design a Wedge Wire Screen or commonly known as Johnson Screen type Catalyst Bed installed in a vessel for wet H2S service according to NACE conditions. The fixed Support grid was to be Johnson Screen support with the profile material to be prepared in Stainless Steel Grade SS 316L.

The Hold down grating was to be designed with upper and lower stop rings in order to prevent the lifting or crushing of bed. The Grating Open Area was to be of a minimum 80%. The Lower stop ring should be approximately 50mm above the top of catalyst balls and the upper stop ring should have approximately 200mm above the top of catalyst balls.

There were three kinds of packings placed on the surface of the bed, 0.5” Ceramic Balls with a 6” height next to top of bed, UOP GB-562S 5×8 adsorbent beads and 0.125”,0.25” and 0.5” ceramic balls with 3” height each next to bottom of bed.

Following were the calculations we performed in order to design and validate the Vessel Internal process design

- Clip analysis

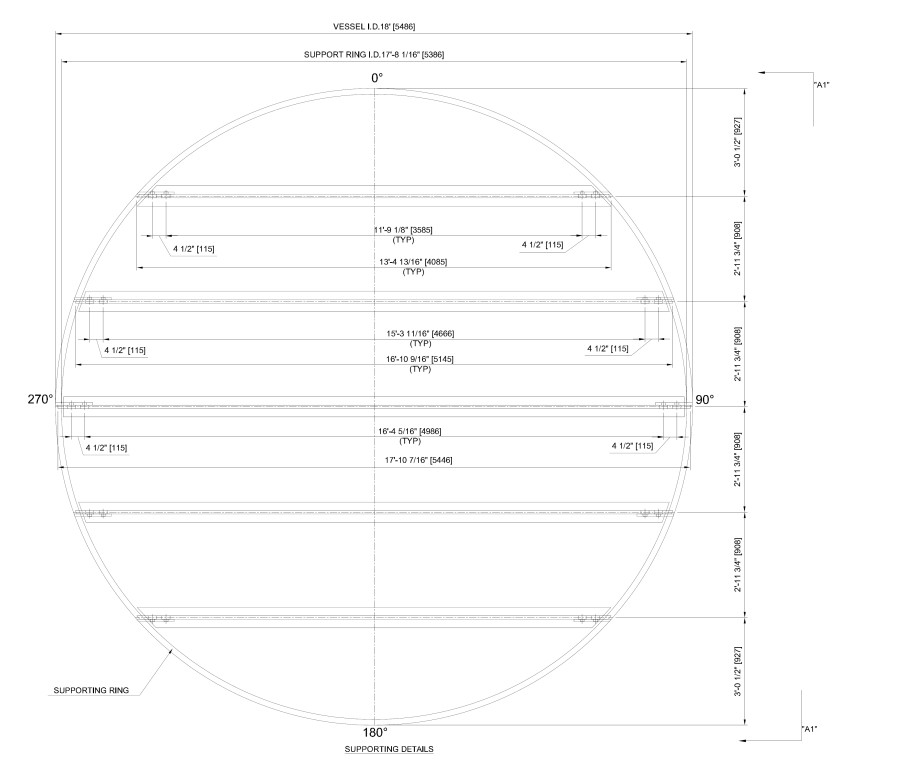

- Support ring analysis

- Support beam analysis

- Cleat and other support analysis

- Grating bed analysis

- Wedge wire screen analysis

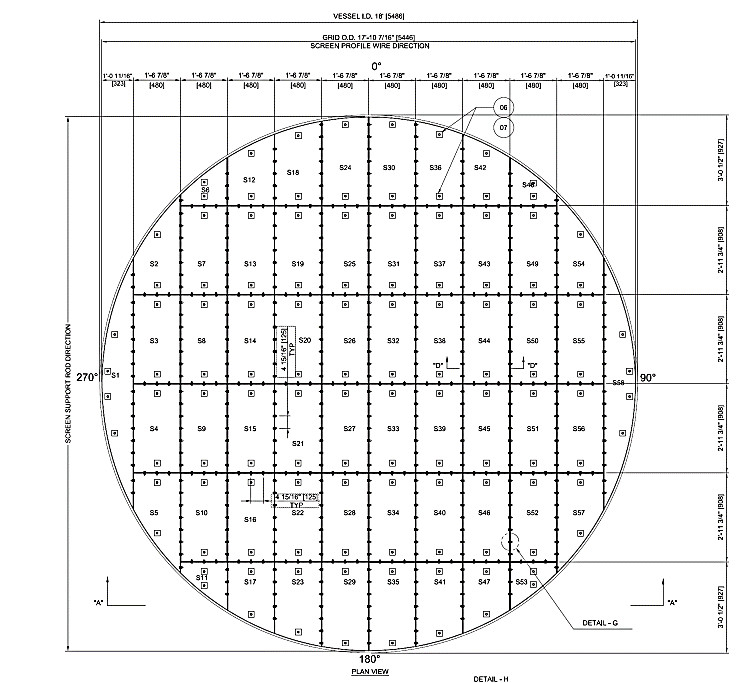

The Vessel ID was 5486 and the pressure drop across the bed was found to be 4900 Kg/m2 with a free area of 86%. The type of support grid suggested was 5 beams with an additional set of gratings.

The section modulus of beam provided was 2720 cm3 which was more than the section modulus of beam required by calculation (2487.1 cm3). The beam gave more than 1mm thickness corrosion allowance by this increased section modulus. The I-beam was therefore set to be designed at 450mmx175mmx30mmx30mm and found to be adequate for operating load.

The section modulus of grating of 2.6 cm3 was more than the theoretical section modulus value of 2.14 cm3, hence the design was found to be satisfactory. The section modulus of the profile wire of 3.51 cm3 was more than the theoretical section modulus of 2.14 cm3. The induced stress in the wire was also less than the allowable bending stress in the profile wire.

For more information, sales inquiries and other queries, please feel free to contact our sales team at sales.export@qualitywire.com.bh